Steel-faced

sandwich panels

faced with galvanized steel with a polymer coating

Scope of use

Steel-faced insulated sandwich panel is comprised of two sheets of galvanized and colored steel and an insulating slab of basaltic mineral wool with laterally-oriented fiber. A galvanized steel sheet with thickness from 0.5 to 0.7 mm has a multilayered polymeric protective and decorative coating.

Sandwich panels with a polymeric coating can be used for construction of hypermarkets, shopping malls, airports and train stations, car dealer centres, and other objects. Color range of sandwich panels we produce is virtually limitless - you can choose and order panels of any RAL color.

Technical characteristics

Panel type

Thickness, mm

Specific weight

kg/m2

kg/m2

Width, mm

Maximum length, mm

Fire resistance

rating, El min

rating, El min

Fire safety

class

class

Thermal

resistance

resistance

Airborne sound

insulation index. dB

insulation index. dB

MP50

50

15

1200 600 - 1190

12000

30

K0(30)

1,16

33

MP60

60

17

1200 600 - 1190

12000

45

К0(45)

1,36

33

MP80

80

19

1200 600 - 1190

12000

45

К0(45)

1,76

33

MP100

100

21

1200 600 - 1190

12000

90

К0(45)

2,16

34

MP120

120

24

1200 600 - 1190

12000

150

К0(45)

2,56

34

MP150

150

27

1200 600 - 1190

12000

150

К0(45)

3,16

34

MP180

180

30

1200 600 - 1190

12000

150

К0(45)

3,87

34

MP200

200

33

1200 600 - 1190

12000

150

К0(45)

4,16

34

MP250

250

39

1200 600 - 1190

12000

150

К0(45)

5,16

34

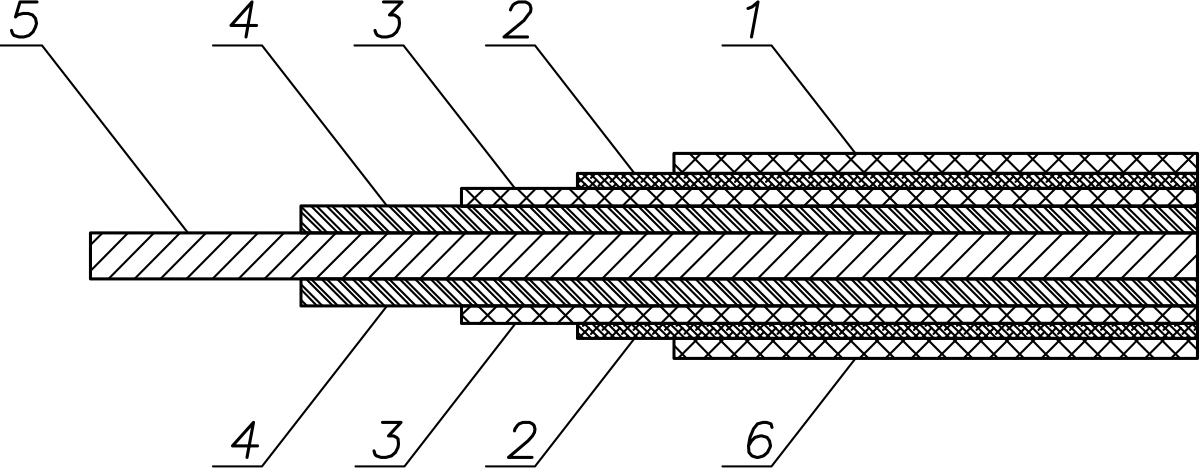

Design of a polymer-coated steel plate.

- Polymer coating

- Primer coating

- Passivation layer

- Zinc coating

- Steel sheet of 0.5 - 1 mm in thickness

- Background colouring

Properties of different polymer coatings

Type of polymer coating

Polyester

Pural

PVF2

Coating thickness, µm

25

50

25-27

Surface

smooth

textured

smooth

Maximum operating temperature, С

+90

+100

+120

Corrosion resistance

SALT SPRAY TEST, Hours

WATER TEST, Hours

500

1000

1000

1000

1000

1000

Resistance to UV

good

good

excellent

Resistance to mechanical damage

fair

good

good

Maintainability

good

excellent

fair