Sandwich wall panels

Sandwich wall panel is a three-layer metal-faced panel with a core of mineral wool. Our sandwich wall panels production process is based on bench manufacturing technology developed by Finnish company OLLIN Matalli OY producing panels since 1985. Wall panels are manufactured in full compliance with the tried and tested technology and technical specifications.

Galvanized steel-faced

faced with galvanized steel with polymeric coatingStainless steel-faced

faced with corrosionproof stainless steelAluminium-faced

faced with aluminium sheetsAcoustic solutions

panels faced with sound absorbing and noise insulating materialGeneral characteristics for sandwich panels with mineral wool core

rating, El min

class

resistance

insulation index. dB

The main advantages of sandwich panels:

- compliance with the hygienic and ecological standards, including civil construction standards;

- high degree of fire resistance;

- high degree of strength and durability;

- resistance to weathering and temperature changes;

- great thermal and noise insulation properties;

- a wide range of RAL colours for the facing metal that does not require any additional finishing;

Strong points of Stroypanel’s products

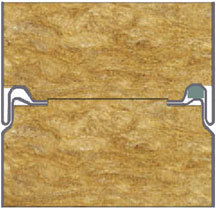

Special design of the interlocks ensures high fireproof, moistureproof and windproof properties of the panels. The protruding piece of mineral wool in the joint tongue provides a dense adjunction of insulation layers of adjacent panels. The joint tongue has two grooves designed for proper installation of the sealing. In order to ensure better resistance of junctions to steam and moisture a sealing is installed inside the interlocking mechanism.

Quality of all materials used for the panels manufacturing is properly confirmed by relevant Russian quality certificates.

A special three-layer design provides high thermal and acoustic insulation. The mid-layer design is based on a unique technology that involves use of laterally-oriented wool-fiber, which allows to protect a building from cold and wind to the fullest extent possible and makes sandwich panels fireproof. Metal facing sheets of our sandwich panels are corrosionproof and resistant to mechanical, physical, and chemical impact.

Therefore, our products are suitable for use in all climatic zones, including the Extreme North.

Factors influencing the price of sandwich panels

- scope of supply and distance to a construction site;

- type of facing materials and intended use of the panels;

- thickness of panels and insulation type;

- type of polymer coating applied on metal facing;;

Price of sandwich panels is determined on a case by case basis.